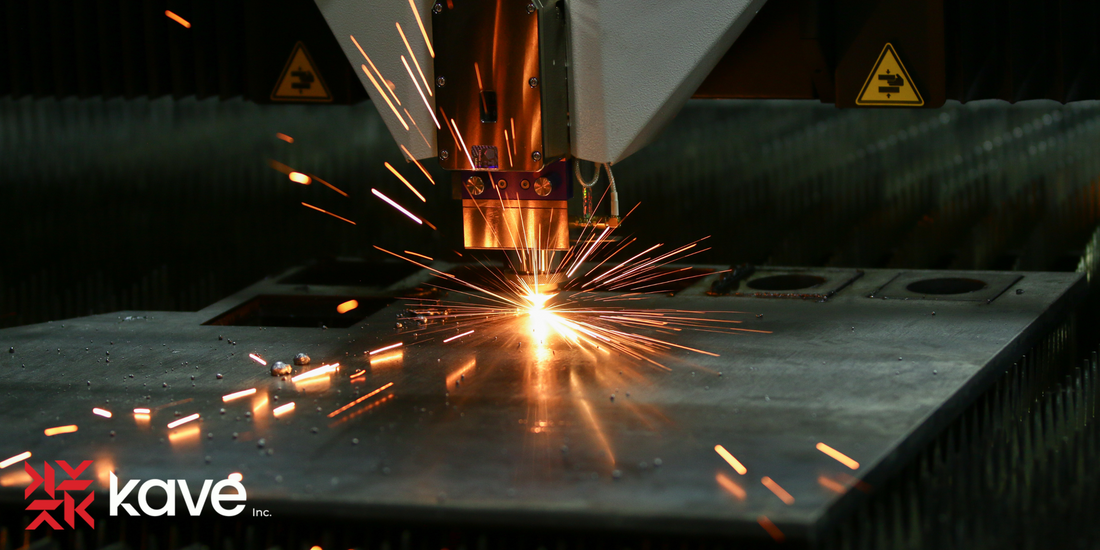

When precision meets efficiency, laser cutting technology delivers unmatched results for businesses across countless industries. From custom prototypes for small businesses to high-volume production for large manufacturers, modern laser cutting services offer the accuracy, speed, and versatility that today’s projects demand.

Why Laser Cutting Services Are Essential in Modern Manufacturing

Laser cutting uses concentrated light beams to cut through materials with extreme accuracy. This process has quickly become a cornerstone of precision fabrication because of its advantages over traditional methods:

-

Unparalleled Precision – Achieve tolerances as tight as ±0.003 inches, ensuring every part meets exact specifications.

-

Versatile Material Compatibility – Cut steel, aluminum, and stainless steel, as well as non-metals like acrylic, plastics, wood, and fabric.

-

Smooth, Finished Edges – Produces clean, burr-free cuts that often require no secondary finishing.

-

Complex Geometries – Handle intricate designs, tight corners, and complex patterns with ease.

Industries That Rely on Professional Laser Cutting

-

Automotive Manufacturing – Chassis parts, brackets, exhaust components, and decorative trims.

-

Aerospace Engineering – Lightweight, high-precision components where failure is not an option.

-

Medical Device Manufacturing – Surgical tools, implant parts, and diagnostic equipment cut to exact standards.

-

Architecture & Construction – Decorative panels, structural supports, and custom architectural elements.

-

Electronics & Technology – Circuit boards, precision housings, and enclosures requiring intricate detail.

Common Types of Laser Cutting

-

CO₂ Laser Cutting – Best for non-metal materials like acrylic, wood, plastics, and fabrics.

-

Fiber Laser Cutting – Ideal for metals such as steel, aluminum, brass, and copper; offers superior speed and efficiency.

-

YAG Laser Cutting – Designed for thicker materials and deep penetration projects.

Choosing the Right Laser Cutting Partner

When selecting a fabrication provider, consider:

-

Material Thickness Capabilities – Ensure they can cut the metals you require at the needed thickness.

-

Turnaround Time – Choose a shop that can meet deadlines without sacrificing quality.

-

Certifications – Look for ISO 9001 or other industry standards.

-

Design Support – Providers that offer CAD/CAM support help optimize your designs for cost and manufacturability.

Maximizing Efficiency with Laser Cutting

Working with a professional fabrication shop helps you:

-

Optimize Designs – Reduce waste and cut costs with smart nesting and design adjustments.

-

Select the Right Materials – Balance performance, cost, and finish requirements.

-

Batch Process Effectively – Combine parts into efficient cutting runs for reduced setup and production costs.

Quality Control in Laser Cutting

Reputable providers like Kave Inc. use strict quality control measures, including:

-

First article inspection before full runs

-

Statistical process control during production

-

Certified material sourcing and traceability

-

Comprehensive final inspections before delivery

The Future of Laser Cutting

The industry is rapidly advancing with:

-

AI-driven optimization for cutting paths and material usage

-

Automation and robotics to streamline production

-

Expanded material capabilities including composites and advanced alloys

-

Sustainability practices to reduce waste and energy use

Why Invest in Professional Laser Cutting Services?

Professional fabrication shops offer advantages beyond in-house capabilities:

-

Access to state-of-the-art equipment

-

Skilled operators and engineers

-

Scalable production from single parts to full runs

-

Rigorous quality assurance

-

Cost savings by eliminating equipment investment and maintenance

Conclusion

Laser cutting is one of the most efficient and precise fabrication methods available today. Whether you’re building custom prototypes or scaling to high-volume manufacturing, the right laser cutting partner ensures accuracy, consistency, and cost-effectiveness.

At Kave Inc., we specialize in laser cutting services for steel, aluminum, stainless steel, and more, delivering clean edges, tight tolerances, and fast turnaround times. From trailers and RVs to automotive, aerospace, and marine applications, our precision fabrication capabilities help bring your projects to life.

👉 Ready to start your next project? Request a Quote today and experience the difference of professional laser cutting services.